Bonded Magnet

TIME:2024-05-28 Bromag Visits:

Bonded NdFeB magnets are a type of permanent magnet made from a mixture of NdFeB powder and a polymer binder, typically epoxy resin. This manufacturing process allows for the production of magnets with complex shapes and configurations that would be difficult or impossible to achieve with traditional machining methods used for sintered NdFeB magnets.

|

Item |

Grade |

Remanence induc/on |

Coercive force |

Intrinsic Coercive force |

Maximum Energy product |

Working Temperat ure |

Density |

Temperature Coefficient of B |

||||

| Br | HcB | HcJ | (BH)max | Tw | ρ | α | ||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | %/℃ | ||

|

Compression Molding NdFeB Magnet |

BM-2 | 0.30~0.40 | 3.0-4.0 | 160~240 | 2.0~3.0 | 480~640 | 6.0~8.0 | 16~24 | 2.0~3.0 | ≤120 | 4.5~6.0 | -0.12 |

| BM-4 | 0.40~0.50 | 4.0~5.0 | 240~320 | 3.0~4.0 | 560~720 | 7.0~9.0 | 32~44 | 4.0~5.5 | ≤120 | 5.2~6.0 | -0.11 | |

| BM-6 | 0.55~0.63 | 5.5~6.3 | 320~400 | 4.0~5.0 | 480~640 | 6.0~8.0 | 48~60 | 6.0~7.5 | ≤120 | 5.5~6.0 | -0.11 | |

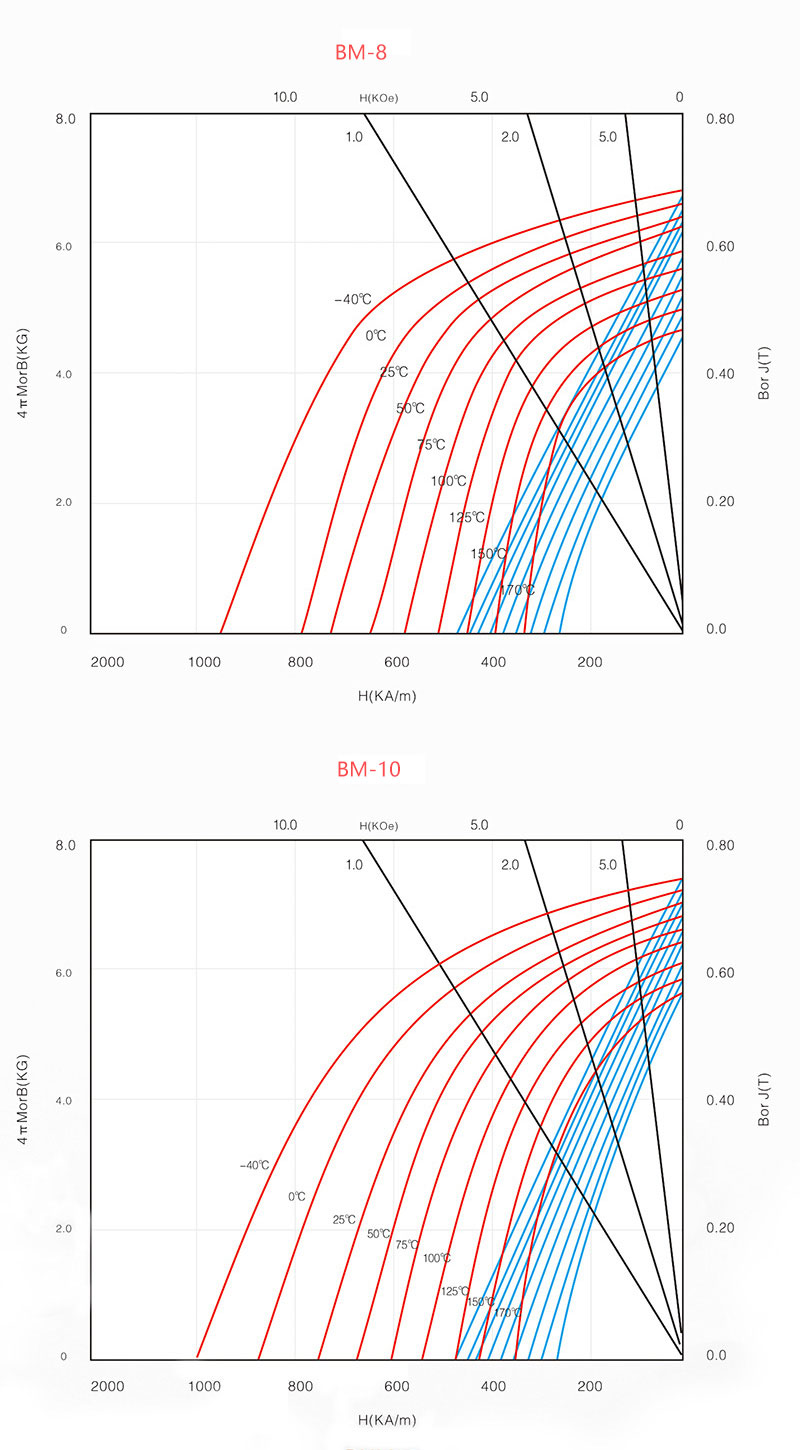

| BM-8 | 0.65~0.68 | 6.5~6.8 | 360~440 | 4.5~5.5 | 640~800 | 8.0~10.0 | 64~72 | 8.0~9.0 | ≤150 | 5.8~6.1 | -0.1 | |

| BM-8H | 0.60~0.65 | 6.0~6.5 | 400~480 | 5.0~6.0 | 1120~1280 | 14.0~16.0 | 60~68 | 7.5~8.5 | ≤160 | 5.8~6.2 | -0.1 | |

| BM-8L | 0.65~0.68 | 6.5~6.8 | 400~480 | 5.0~6.0 | 900~1120 | 11.0~14.0 | 64~72 | 8.0~9.0 | ≤160 | 5.8~6.2 | -0.1 | |

| BM-9 | 0.60~0.68 | 6.0~6.8 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 68~72 | 8.5~9.0 | ≤150 | 5.8~6.2 | -0.1 | |

| BM-10 | 0.68~0.73 | 6.8~7.3 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 76~84 | 9.5~10.5 | ≤150 | 5.8~6.2 | -0.1 | |

| BM-12 | 0.71~0.75 | 7.1~7.5 | 440~520 | 5.5~6.5 | 720~800 | 9.0~10.0 | 84~96 | 10.5~12.0 | ≤150 | 6.0~6.2 | -0.1 | |

| BM-12L | 0.72~0.76 | 7.2~7.6 | 400~480 | 5.0~6.0 | 480~640 | 6.0~8.0 | 84~96 | 10.5~12.0 | ≤140 | 6.0~6.2 | -0.12 | |

| Injection Molding NdFeB Magnet | Bl-3 | 0.25~0.35 | 2.5~3.5 | 160~240 | 2.0~3.0 | 480~640 | 6.0~8.0 | 12~24 | 1.5~3.0 | ≤120 | 3.9~4.4 | -0.12 |

| BI-4 | 0.35~0.45 | 3.5~4.5 | 240~320 | 3.0~4.0 | 560~720 | 7.0~9.0 | 24~36 | 3.0~4.5 | ≤120 | 4.2~4.9 | -0.11 | |

| BI-5 | 0.45~0.52 | 4.5~5.2 | 320~360 | 4.0~4.5 | 560~720 | 7.0~9.0 | 36~44 | 4.5~5.5 | ≤120 | 4.5~5.0 | 0.11 | |

| BI-5H (PPS) | 0.48~0.52 | 4.8~5.2 | 400~480 | 5.0~6.0 | 880~1040 | 11.0~13.0 | 36~44 | 4.5~5.5 180 | ≤180 | 4.9~5.4 | -0.1 | |

| KBI-6 | 0.50~0.55 | 5.0~5.5 | 320~440 | 4.0~5.5 | 640~800 | 8.0~10.0 | 44~52 | 5.5~6.5 | ≤120 | 4.7~5.1 | -0.11 | |

| KBI-7 | 0.58~0.64 | 5.8~6.4 | 320~400 | 4.0~5.0 | 640~800 | 8.0~10.0 | 52~60 | 6.5~7.5 | ≤120 | 5.0~5.5 | -0.11 | |

| KBI-8 | 0.64~0.74 | 6.4~7.4 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 68~76 | 8.5~9.5 | ≤120 | 5.5~5.9 | -0.11 | |

| BI-F1.5 | 0.22~0.24 | 2.2~2.4 | 160~167 | 2.00~2.10 | 231~240 | 2.90~3.00 | 11.6~12.4 | 1.45~1.55 | / | 3.25 | -0.19 | |

| Injection Molding Ferrite Magnet | BI-F1.9 | 0.27~0.29 | 2.7~2.9 | 180~186 | 2.25~2.33 | 216~228 | 2.70~2.85 | 14.8~15.6 | 1.85~1.95 | / | 3.63 | -0.19 |

| BI-F2.0 | 0.28~0.29 | 2.8~2.9 | 184~200 | 2.30~2.50 | 216~246 | 2.70~3.10 | 15.6~16.4 | 1.95~2.05 | / | 3.7 | -0.19 | |

| BI-F2.1 | 0.28-0.29 | 2.8~2.9 | 190~204 | 2.38~2.55 | 224~249 | 2.80~3.12 | 16.4~17.2 | 2.05~2.15 | / | 3.75 | -0.19 | |

| Bl- | 0.25~0.26 | 2.5~2.6 | 167~175 | 2.10~2.20 | 208~216 | 2.60~2.70 | 13.6~14.0 | 1.70~1.75 | / | 3.65 | -0.19 | |

| F1.7(PPS) | ||||||||||||