Hard Ferrite

TIME:2024-05-28 Bromag Visits:

Ferrite magnets,

also known as ceramic magnets, are a type of permanent magnet made from iron oxide (Fe2O3) combined with other metallic elements, typically strontium or barium. They are the most widely used type of permanent magnets due to their low cost, high magnetic strength, and resistance to corrosion.

Ferrite magnets have a high coercivity, meaning they are difficult to demagnetize once magnetized. They are brittle and can break easily, so they are often coated or plated to protect them from chipping or shattering.

These magnets find applications in various industries, including automotive, electronics, telecommunications, and manufacturing. They are commonly used in speakers, magnetic separators, motors, and magnetic resonance imaging (MRI) machines, among other devices.

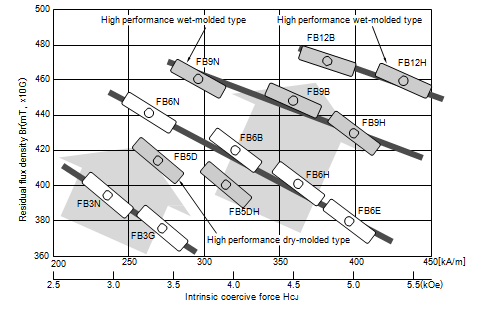

Ferrite Characteristic Distribution Diagram

| Material Grade | Br Residual Flux Density | Coercive Force | Intrinsic Coercive Force | Max Energy Product | ||||

| mT | Gs | KA/m | Oe | KA/m | Oe | Kj/m3 | MGOe | |

| BM10T | 210-240 | 2100-2400 | 127-159 | 1600-2000 | 211-279 | 2650-3500 | 6.4-9.5 | 0.8-1.2 |

| BM20J | 245-290 | 2450-2900 | 151-191 | 1900-2400 | 239-279 | 3000-3500 | 10.3-16.7 | 1.3-2.1 |

| BM20 | 350-370 | 3500-3700 | 135-167 | 1700-2100 | 140-171 | 1750-2150 | 22.3-27.1 | 2.8-3.4 |

| BM25 | 380-400 | 3800-4000 | 143-175 | 1800-2200 | 147-179 | 1850-2250 | 25.5-29.6 | 3.2-3.7 |

| BM30 | 390-410 | 3900-4100 | 175-207 | 2200-2600 | 179-211 | 2250-2650 | 27.1-31.2 | 3.4-3.9 |

| BM33H | 390-410 | 3900-4100 | 239-271 | 3000-3400 | 243-275 | 3050-3450 | 27.1-31.2 | 3.4-3.9 |

| BM34H | 370-390 | 3700-3900 | 263-291 | 3300-3650 | 307-330 | 3850-4150 | 24.7-28.7 | 3.1-3.6 |

| BM3845 | 370-390 | 3700-3900 | 263-299 | 3300-3750 | 342-378 | 4300-4750 | 25.5-28.7 | 3.2-3.6 |

| BM3850 | 370-390 | 3700-3900 | 267-303 | 3350-3800 | 382-406 | 4800-5100 | 25.5-28.7 | 3.2-3.6 |

| BM4036 | 395-415 | 3950-4150 | 263-291 | 3300-3650 | 279-303 | 3500-3800 | 28.7-31.8 | 3.6-4.0 |

| BM4040 | 390-410 | 3900-4100 | 271-295 | 3400-3700 | 307-326 | 3850-4100 | 28.7-31.8 | 3.6-4.0 |

| BM4129 | 400-420 | 4000-4200 | 215-239 | 2700-3000 | 219-243 | 2750-3050 | 29.6-32.8 | 3.7-4.1 |

| BM4229 | 415-435 | 4150-4350 | 215-239 | 2700-3000 | 219-243 | 2750-3050 | 30.3-33.4 | 3.8-4.2 |

| BM4240 | 410-430 | 4100-4300 | 283-307 | 3550-3850 | 307-330 | 3850-4150 | 31.2-35.2 | 3.9-4.4 |

| BM4433 | 430-450 | 4300-4500 | 247-271 | 3100-3400 | 251-275 | 3150-3450 | 33.4-36.6 | 4.2-4.6 |

| BM4045 | 390-410 | 3900-4100 | 287-310 | 3600-3900 | 358-382 | 4500-4800 | 28.7-31.8 | 3.6-4.0 |

| BM4350 | 420-440 | 4200-4400 | 294-326 | 3700-4100 | 386-410 | 4850-5150 | 33.4-36.6 | 4.2-4.6 |

| BM4545 | 440-460 | 4400-4600 | 318-350 | 4000-4400 | 347-370 | 4350-4650 | 36.6-39.8 | 4.6-5.0 |

| BM4636 | 450-470 | 4500-4700 | 255-279 | 3200-3500 | 275-299 | 3450-3750 | 38.3-41.5 | 4.8-5.2 |

| BM4550 | 440-460 | 4400-4600 | 303-334 | 3800-4200 | 374-406 | 4700-5100 | 35.9-39.1 | 4.5-4.9 |