铝镍钴

发布时间:2021-04-01 作者:admin 浏览次数:次

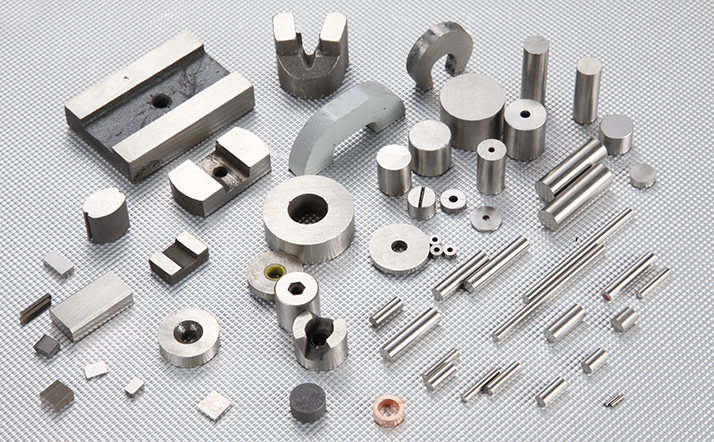

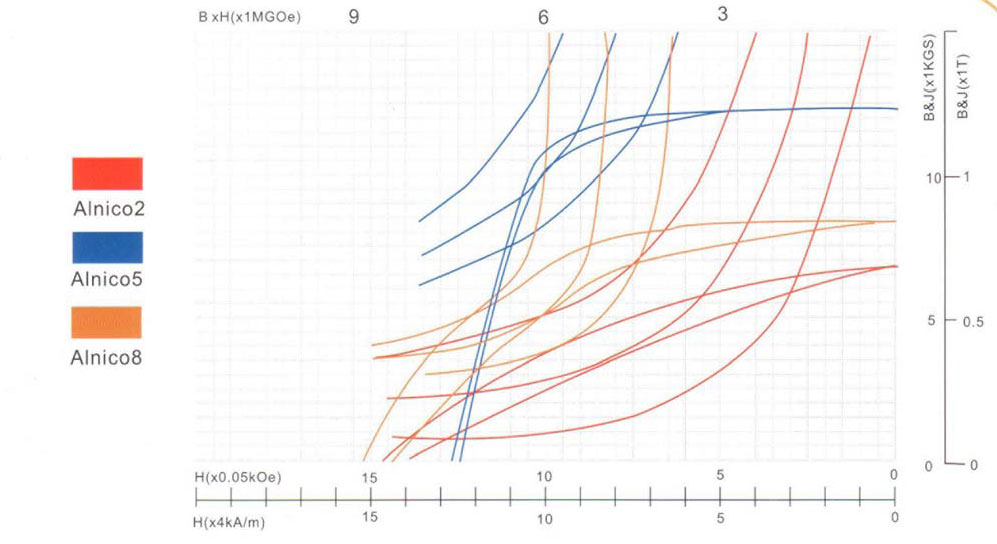

产品说明产品图片性能曲线

|

Grade |

Br | Hcb | (BH)max | Tc. | Tw. | aBr |

MMPA Equivalent |

IEC Equivalent |

Germany Standard | |||

| mT | Gs | KA/m | Oe | Kj/m3 | MGOe | [°C] | [°C] | [%°C] | ||||

| *LN9 | 690 | 6900 | 37 | 470 | 9 | 1.13 | 760 | 500 | -0.03 |

Alnico3 |

Alnico9/4 |

Alnico120 |

| *LN10 | 600 | 6000 | 40 | 500 | 10.0 | 1.25 | 760 | 500 | -0.03 | |||

| *LNG12 | 720 | 7200 | 44 | 550 | 12.0 | 1.50 | 810 | 500 | -0.03 |

Alnico2 |

Alnico12/6 |

Alnico160 |

| *LNG13 | 700 | 7000 | 48 | 600 | 13.0 | 1.63 | 810 | 500 | -0.03 | |||

| LNG16 | 800 | 8000 | 53 | 660 | 16.0 | 2.00 | 850 | 500 | -0.02 |

Alnico4 |

/ |

/ |

| LNG18 | 1050 | 10500 | 48 | 600 | 30.0 | 3.75 | 850 | 500 | -0.02 | |||

| LNG32 | 1180 | 11800 | 44 | 550 | 32.0 | 4.00 | 890 | 500 | -0.02 |

Alnico5C |

/ |

Alnico500 |

| LNG34 | 1180 | 11800 | 44 | 550 | 34.0 | 4.25 | 890 | 500 | -0.02 | |||

| LNG37 | 1200 | 12000 | 48 | 600 | 37.0 | 4.65 | 890 | 500 | -0.02 |

Alnico5 |

Alnico37/5 |

Alnico500 |

| LNG40 | 1250 | 12500 | 48 | 600 | 40.0 | 5.00 | 890 | 500 | -0.02 | / | ||

| LNG44 | 1250 | 12500 | 52 | 650 | 44.0 | 5.50 | 890 | 500 | -0.02 | Alnico44/5 | ||

| LNG48 | 1250 | 12500 | 52 | 650 | 48.0 | 6.00 | 890 | 500 | -0.02 |

Alnico5DG |

Alnico52/6 |

Alnico 600GD |

| LNG52 | 1300 | 13000 | 56 | 700 | 52.0 | 6.50 | 890 | 500 | -0.02 | |||

| LNG60 | 1350 | 13500 | 56 | 700 | 60.0 | 7.50 | 890 | 500 | -0.02 | Alnico5~7 | / | Alnico700 |

| LNGT28 | 1050 | 10500 | 56 | 700 | 28.0 | 3.50 | 860 | 500 | -0.02 | Alnico6 | Alnico26/6 | Alnico400 |

| *LNGT18 | 580 | 5800 | 90 | 1130 | 18.0 | 2.20 | 860 | 500 | -0.03 | Alnico7 | Alnico17/9 | Alnico260 |

| LNGT32 | 800 | 8000 | 100 | 1250 | 32.0 | 4.25 | 860 | 500 | -0.03 |

Alnico8 |

/ |

Alnico350 |

| LNGT34 | 800 | 8000 | 104 | 1300 | 34.0 | 4.25 | 860 | 500 | -0.03 | |||

| LNGT38 | 820 | 8200 | 110 | 1380 | 38.0 | 4.75 | 860 | 500 | -0.03 | Alnico38/11 |

Alnico450 |

|

| LNGT44 | 880 | 8800 | 120 | 1500 | 44.0 | 5.50 | 860 | 500 | -0.03 |

/ |

||

| LNGT48 | 900 | 9000 | 120 | 1500 | 48.0 | 6.00 | 860 | 500 | -0.03 | |||

| LNGT60 | 900 | 9000 | 110 | 1380 | 60.0 | 7.50 | 860 | 500 | -0.03 |

Alnico9 |

Alnico60/11 |

/ |

| LNGT72 | 1050 | 1050 | 112 | 1410 | 72.0 | 9.00 | 860 | 500 | -0.03 |

/ |

||

| LNGT82 | 1100 | 11000 | 120 | 1500 | 82.0 | 10.25 | 860 | 500 | -0.03 | |||

| LNGT88 | 1100 | 11000 | 120 | 1500 | 88.0 | 11.00 | 860 | 500 | -0.03 |

/ |

||

| LNGT92 | 1120 | 11200 | 120 | 1500 | 92.0 | 11.50 | 860 | 500 | -0.03 | |||

| LNGT36J | 700 | 7000 | 140 | 1750 | 36.0 | 4.50 | 860 | 500 | -0.03 | Alnico8HC | Alnico36/15 | Alnico450 |

Note:* means Isotropy.

Physical Properties of Cast Alnico Magnets

| Curie Temperature | 760-890℃ |

| Max.Operating Temperature | 450-550℃ |

| Resistivity | 47-54μ Ohm.cm |

| Vickers Hardness | 520-630Hv |

| Density | 6.9-7.3g/cm³ |

| Relative Recoil Permeability | 1.7-4.7μrec |

| Saturation Field Strength | 2.7-6.3kOe/215-500kA/m |

| Temperature Coefficient of Remanence(Br) | -0.025~-0.02%/℃ |

| Temperature Coefficient of Remanence(iHc) | +0.01~0.03%/℃ |

Typical Demagnetizing Curves of Cast Alnico

在线咨询

在线咨询 微信公众账号

微信公众账号